| THIN FILM HEAT FLUX SENSOR WITH ENCAPSULATION - LARGE | ||||

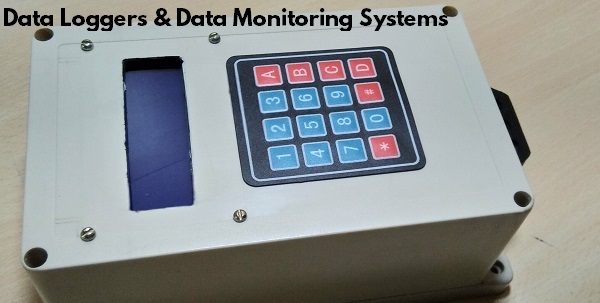

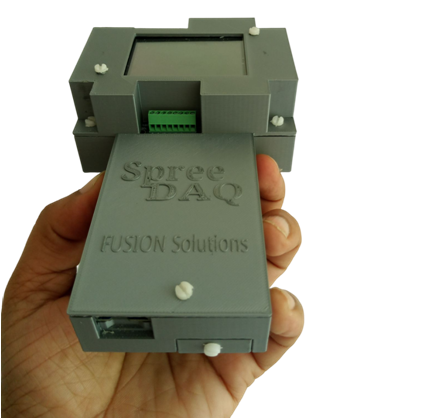

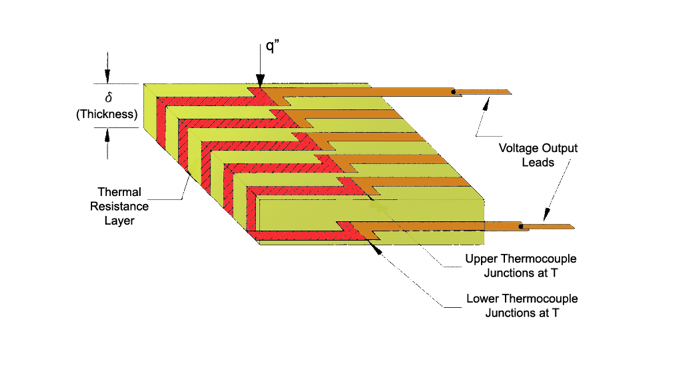

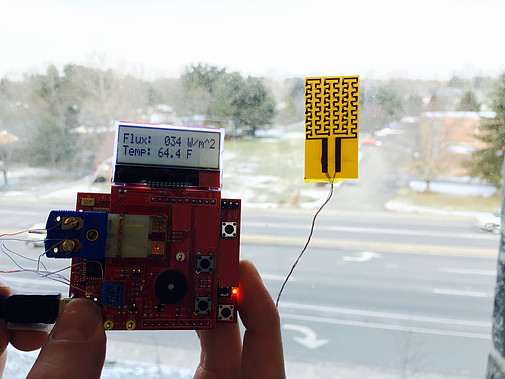

Heat Flux Measurement Technique relies on Heat Flux Sensors. These sensors are most economically priced, but still equally reliable sensors available in the world market.It has minimal thickness while still maintaining excellent sensitivity. This sensor is recommended for permanent placement use such as long term thermal monitoring of windows, walls, ducts, pipes, etc |

||||

|

||||

| These sensors are available in TWO versions. One is basic sensor and another one is the encapsulated version in which sensor is encapsulated in either copper, brass, or aluminum to make it more robust. With the encapsulation, the sensor still maintains excellent sensitivity while increasing durability necessary to withstand being removed and reapplied to surfaces multiple times | ||||

; ; |

; ; |

|||

|

||||

| SPECIFICATIONS | ||||

Sensor type |

Differential Thermopile |

|||

| Encapsulation | Copper(Other materials available) | |||

Nominal Sensitivity |

Approx. 70 - 90 mV/(W/cm^2) |

|||

| Sensor thickness (t) | 560 microns |

|||

Heat Flux range |

+/- 150 kW/m^2 |

|||

Response Time |

0.9 Seconds |

|||

| Sensor Surface Thermocouple | Type-T | |||

| Sensing Area Dimensions | a=8.8 cm b=9.5 cm | |||

Operating Temperature Range |

-50 to +120 degC |

|||

| APPLICATIONS | ||||

| Thermal monitoring of buildings: The sensors can be placed on windows and walls to determine where heat is being lost at certain times of the day and in certain whether conditions. For example, wind or rain hitting a building from a certain direction will cause more heat transfer on the side exposed to these conditions. Sensing this can help determine where to direct heating or cooling in specific zones of buildings to save energy. | ||||

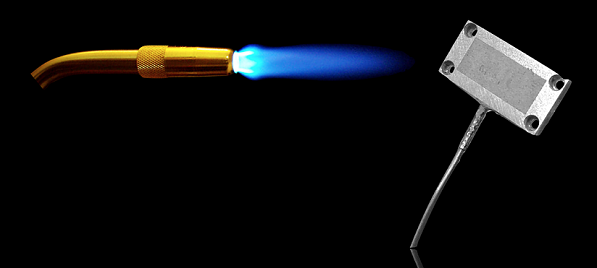

| Thermal properties of materials: Knowledge of the thermal properties of certain materials is essential for a wide variety of applications. Heat flux sensors can be used in conjunction with thermocouples and an applied heat in order to determine essential thermal properties of materials such as thermal conductivity. | ||||

| Wearable technology: The direct measurement of heat flux is the most accurate method to estimate calories burned. The body responds differently with different exercises and in different climate conditions. Heat flux sensors can help to constantly keep track of how much heat a body is losing in such conditions. | ||||

| R&D: Heat transfer is critical to any R&D having to do with thermal management, thermal monitoring, and energy efficiency. Heat flux sensors can be used in a variety of ways to make R&D in the field of heat transfer much easier and commercial products can be built around the sensors. For example, research has been done to use heat flux sensors to estimate blood perfusion in organs. | ||||

Heat Transfer Education: It should come as a surprise that heat transfer classes are taught to engineering students all across the country without the students actually measuring heat flux. This lack of hands-on experience with heat flux causes students to confuse heat and temperature and the underlying concepts in the subject. Heat transfer workshops have been designed and created which use heat flux sensors in a variety of situations to help students learn heat transfer hands-on and through the combined measurement of heat flux and temperature. |

||||

These Heat Flux Sensors are also available in various other dimensions |

||||

..one stop store for your needs